Maintaining your crane equipment is not just about ensuring it works on the day; it's about prolonging its lifespan and ensuring safety at all levels of operation. In this blog post, we'll delve into the critical maintenance practices that keep cranes operating efficiently and safely over time. These practices are essential for the machinery's longevity and pivotal in preventing costly breakdowns and ensuring every project runs smoothly. Let's explore some essential maintenance tips that every crane operator should prioritise.

1. Prioritise Regular Inspections for Safety & Efficiency

When it comes to crane maintenance, the importance of regular inspections cannot be overstated. These inspections, carried out by qualified professionals, help catch small issues before they escalate into major problems. Routine checks ensure the equipment operates safely and efficiently, reducing downtime and enhancing productivity.

A qualified technician can identify early signs of wear and tear, such as:

Scheduling regular inspections is more than just ticking a box for compliance—it’s an investment in your crane’s longevity. Inspections can also help ensure that your machinery complies with local regulations and safety standards.

2. Ensure Proper Lubrication to Avoid Costly Repairs

Lubrication is one of the most basic yet critical aspects of crane maintenance. When components aren’t properly lubricated, they experience higher levels of friction, which accelerates wear and tear. Over time, this can lead to significant mechanical failures, leaving your crane needing expensive repairs.

The key here is to ensure that lubrication is done correctly, using the appropriate products for each part of the crane. A professional technician can ensure that:

Regular lubrication protects your equipment but also leads to long-term savings. When moving parts are lubricated correctly, they operate more smoothly, reducing strain on the motor and other vital components.

3. Address Minor Issues Promptly with Expert Repairs

Minor issues in crane components can quickly evolve into costly problems if left unaddressed. For example, a slight issue with the hoist can eventually affect the entire lifting system, causing major operational setbacks. By addressing these problems promptly, you can avoid a full-scale breakdown and keep your projects on schedule.

Here are some common minor issues to keep an eye on:

Hiring a professional for timely repairs ensures these issues are resolved before they become bigger, costlier problems.

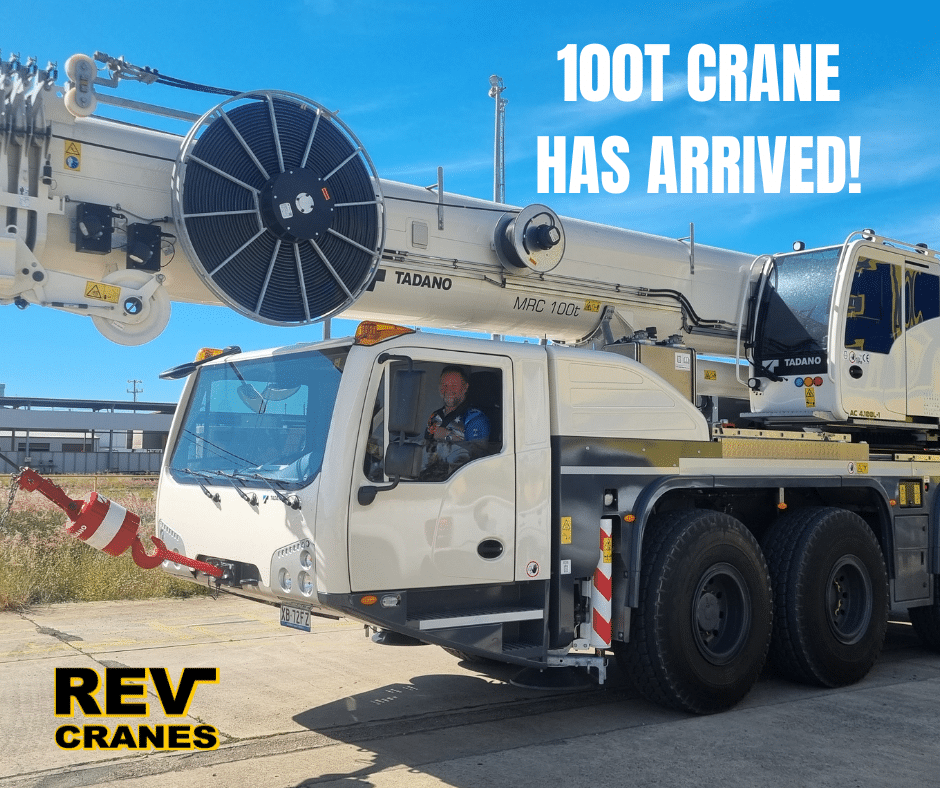

Reach Out to Us for Comprehensive Crane Hire in Queensland

At REV Cranes, safety and efficiency drive us forward. Our dedication to maintaining high safety standards through skilled personnel and well-maintained equipment is central to our service promise. Why settle for less when you can benefit from our proven safety and efficiency track record? Get in touch with us today to learn more about our crane services.