Safety starts with skilled people using good equipment

As part of the crane industry, nearly all of what we do is high risk work. That’s why we’re proud of our safety record. And our safety record comes from having highly skilled personnel operating well maintained, modern cranes and equipment, all working under the umbrella of a modern, comprehensive safety system.

At REV Cranes we make sure it’s a priority that everyone gets to go home safe at the end of the day. And because of that we’ll put our work history up as one of the safest in the industry. We don’t outsource our risk, having built the expertise in-house.

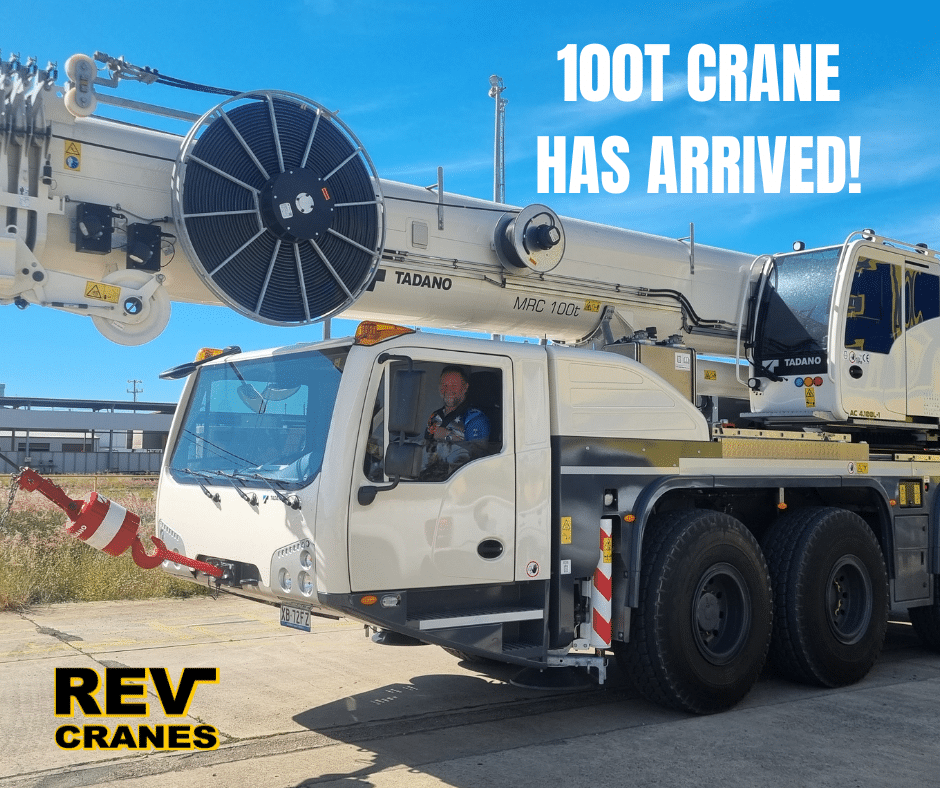

As a member of the Crane Industry Council of Australia, we comply with CraneSafe and stay abreast of developments in the industry. We keep our machines and lifting equipment in great working order, and our people are some of the best in the business.